Effective humidity control plays a critical role in preserving structural integrity, preventing microbial growth, and ensuring operational efficiency in commercial and industrial facilities. Excessive moisture can lead to corrosion of metal components, degradation of stored goods, and elevated energy consumption by HVAC systems. According to the U.S. Environmental Protection Agency, “Indoor relative humidity (RH) should be kept below 60 percent — ideally between 30 percent and 50 percent, if possible” (US EPA). Building Science Corporation underscores that “Elevated relative humidity at a surface – 70 percent or higher – can lead to problems with mold, corrosion, decay and other moisture related deterioration” (buildingscience.com). This article examines maintenance and troubleshooting tips for dehumidification systems, concentrating on industrial dehumidifier types, installation practices, routine upkeep, and diagnostics. Each section references data-driven guidelines to facilitate informed decision-making and reliable performance.

Dehumidifier Types and Operation Modes

Selection of an appropriate dehumidifier hinges on application-specific dehumidifiers, ambient temperature considerations, and capacity requirements. The two primary technologies are:

-

Desiccant vs Refrigerant Dehumidifiers

Desiccant machines use hygroscopic materials to adsorb moisture and excel at low-temperature dehumidification, operating effectively below 5 °C. Refrigerant dehumidifiers draw air over chilled coils, condensing water vapor; efficiency diminishes as ambient temperatures drop. -

Absorbent Dehumidifier Overview

Desiccant systems often incorporate rotating wheels coated with silica gel or molecular sieves. These absorbent dehumidifiers maintain performance in cold, humid environments where refrigerant units underperform. -

Industrial Dehumidifier Types

-

Portable Commercial Units: Flexible, wheeled designs suited for spot drying and temporary installations.

-

Fixed Installation Dehumidifiers: Permanently mounted units integrated with ductwork for whole-building moisture control.

-

High-Capacity Moisture Extractors: Capable of removing hundreds of liters per day; selected via a dehumidifier capacity calculator that factors in determining moisture load, selecting CFM rating, and sizing for warehouse space.

-

Energy-Efficient Models: Employ variable-speed fans and modulating refrigeration circuits to optimize power draw during partial-load conditions.

-

-

Operation Modes

Continuous vs intermittent operation influences energy consumption and humidity stability. Continuous duty reduces humidity spikes but may incur higher electrical costs, whereas intermittent cycling relies on humidistat set-points to activate the system when RH exceeds thresholds.

A commercial dehumidifier comparison should consider parameters such as moisture removal rate, power consumption (often expressed in liters per kilowatt-hour), inlet/outlet temperatures, and noise levels. Application factors—manufacturing environments, cold storage, data centers—dictate the choice between general-purpose units and specialized dehumidifiers designed for explosion-proof or clean-room compliance.

Installation and Commissioning

Correct installation establishes the foundation for long-term performance. Professionals adhere to a safety compliance checklist and implement the following site preparation steps:

-

Site Preparation Steps

Ensure level concrete pads or steel frames, unobstructed clearances around intake and discharge ports (minimum 1 m), and load-bearing supports aligned with manufacturer specifications. -

Ducting and Airflow Setup

Duct systems should employ rigid metal to minimize pressure loss. Avoid flexible ducting longer than 3 m to prevent moisture accumulation and microbial growth. -

Electrical Requirements Guide

Verify voltage drop does not exceed 3 percent at full load. Dedicated breakers, surge protection, and proper grounding are essential for fixed installation dehumidifiers. -

Mounting Best Practices

Anchors must resist dynamic vibration. Rubber isolators dampen noise and prevent structure-borne transmission. -

Condensate Drainage Options

Gravity drains require a minimum 1 percent slope. Where elevation prevents gravity flow, use condensate pumps with auto-restart features and check valves to avoid backflow. -

Professional Installation Tips vs DIY Pitfalls

Licensed technicians should perform final wiring and refrigerant charge adjustments. Common DIY installation pitfalls include undersized wiring, improper refrigerant levels, and inadequate condensate routing. -

System Commissioning and Placement Optimization

After energizing the unit, technicians verify airflow rates with an anemometer, measure inlet/outlet dew points, and calibrate the humidistat to desired RH. Position sensors away from direct airflow and heat sources to avoid false readings.

Routine Maintenance Practices

Scheduled maintenance preserves dehumidifier efficiency and mitigates unplanned downtime. A preventive maintenance checklist typically includes:

-

Routine Filter Cleaning

Wash or replace air filters based on pressure drop indicators. Filters clogged beyond 200 Pa differential require immediate attention to prevent coil frosting. -

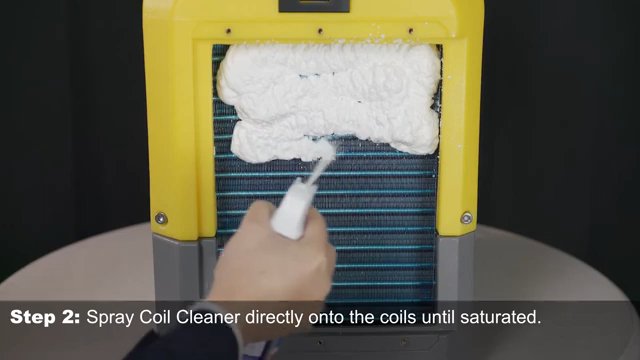

Coil Maintenance Schedule

Quarterly inspection of evaporator and condensing coils. Use soft-brush cleaning to remove dust and scale. Acid-based coil cleaners may be required if microbial sliming is evident. -

Drain Line Unclogging

Annual flushing with a 50:50 water-vinegar solution prevents biofilm buildup. Install access ports for visual inspection of P-traps. -

Refrigerant Leak Checks

Conduct semi-annual electronic leak detection; the average industrial dehumidifier contains 2–3 kg of refrigerant. ASHRAE Standard 15 recommends leak rates below 0.5 percent of charge per year to limit environmental impact. -

Calibration of Humidistat

Cross-check readings against a chilled-mirror hygrometer. A drift exceeding ±2 percent RH mandates recalibration or replacement. -

Noise Reduction Techniques

Inspect fan bearings and motor mounts for wear. Replace belts showing >5 mm elongation. Confirm tightness of dampers and panels to reduce rattling. -

Professional Service Intervals

Invite certified service providers annually for detailed inspections of electrical components, defrost cycles, and control logic.

Troubleshooting Common Issues

Dehumidifier diagnostic features simplify fault resolution. Common error codes and their remedies include:

| Error Code | Indicator | Possible Cause | Recommended Action |

|---|---|---|---|

| E1 | Humidistat Fail | Sensor circuit open or shorted | Inspect wiring; replace sensor |

| E2 | Coil Frost | Low ambient temperature; insufficient defrost | Adjust defrost cycle duration |

| E3 | Fan Stall | Motor overload; obstructed impeller | Clear debris; test motor amp draw |

| E4 | High Pressure | Blocked condenser airflow | Clean coils; verify refrigerant charge |

-

DIY Repair Tips

Before any intervention, isolate power and lock out tag out. Minor sensor replacements can be performed with basic hand tools using manufacturer-supplied parts. Always verify repair with system self-test mode. -

SEER vs EER Explained

Seasonal Energy Efficiency Ratio (SEER) reflects performance over a cooling season; Energy Efficiency Ratio (EER) denotes efficiency under fixed conditions (e.g., 27 °C ambient, 35 °C condensing). Industrial humidity requirements often prioritize EER for predictable load scenarios.

Long-Term Performance and Return on Investment

Lifecycle cost analysis reveals that energy-efficient models and proper maintenance yield lower total cost of ownership. Key considerations include:

-

Long-Term ROI

Facilities management studies indicate that a 10 percent improvement in EER reduces annual energy costs by approximately 8 percent. For a 50-kW dehumidifier running 5,000 h/year, savings can exceed €2,000 annually. -

Humidity Control Guidelines

Maintain RH set-points within 40 percent to 55 percent to balance comfort, microbial control, and energy use. Excessively low humidity (<30 percent) can induce static buildup, while elevated humidity increases corrosion risk.

Summary of Best Practices

Maintaining effective dehumidification demands an integrated approach encompassing proper sizing, meticulous installation, scheduled maintenance, and systematic troubleshooting. Use a dehumidifier capacity calculator when designing to ascertain precise moisture removal needs. Account for ambient temperature considerations and warehouse space volume when selecting CFM rating and device type. Industry guidelines emphasize preventive maintenance—routine filter cleaning, coil inspections, and refrigerant leak checks—to sustain performance. Familiarity with common error codes and basic diagnostic procedures facilitates swift repairs. Finally, evaluating SEER vs EER metrics and projecting long-term ROI ensures that humidity control installations deliver reliable service at optimized cost.